| Topic: |

Battery powered

36 Watt fluorescent light for light painting cars

|

|

Author/Copyright:

|

John Jovic

|

This article describes the

construction of a compact and portable 12 volt powered 36 Watt fluorescent light (not

LED) which is suitable for light painting cars at night or it could be

used for other painting with light applications.

|

|

|

| The

light is a standard 36W household fluorescent tube in a sturdy housing. The tube

is approx 1200mm long! |

|

Battery powered, in this

case with 1 hours worth of AA NiMH goodness!

|

The light is built into an aluminium housing

which is compact and light enough to use

comfortably. This housing contains the 36 Watt fluorescent tube which is 1200mm

in length, the

electronics (the inverter) which converts the 12 volt from an

external battery or power source into the high voltage needed to

operate the fluorescent tube, a power socket and a power switch.

Nuts and bolts

WARNING: Fluorescent lights and inverters are high voltage devices so

are potentially dangerous. If you don't know how to safely wire, or

operate these kinds of devices then do not attempt to do so, and if you

do, then do so at your own risk.

The principals described below can be modified to suit your own

application so you could build a light which uses multiple tubes or

possibly tubes of greater length and power. Ultimately everything will

need to fit around the inverter that you use so selecting an inverter is

really the starting point.

A brief parts list, listing only the major components, is as follows.

The cost will depend on the components used and the most expensive will

probably be the inverter.

| Item |

Approximate Cost |

| 12 volt

to 36W Fluorescent Inverter (to suit 36W-40W tube) |

$50 |

| T8 36W

fluorescent tube to suit |

$4-20 |

| T8

fluorescent lamp holders (or tombstones) |

$2 each |

| on/off

switch |

$3 |

| input

socket(s) |

$3 |

| fuse

holder/fuse |

$5 |

| aluminium

case, fasteners, wire, Velcro, tape, heat shrink etc. |

$10-30 |

| suitable

battery |

? |

|

|

| |

18 (left) and 36 Watt (right)

lamps are show here for comparison. The 18W fluorescent lamp is described in the

article Battery powered

18 Watt fluorescent light for light painting cars. |

The Fluorescent Inverter is a

form of Electronic Ballast and is the

heart of the light as it converts a low voltage direct current (DC)

into a high frequency high voltage alternating current (AC) which is

applied to each of the 2 filaments at the ends of the fluorescent tube.

Note that Fluorescent Inverters are not normal DC to AC Inverters which are designed to convert

DC to household voltages at 50/60Hz. Also note that normal Electronic Ballasts

typically work at mains voltages and not from low voltage DC sources. Fluorescent inverters are

available in many configurations of input voltage and output load (type

of fluorescent light) so choose one which suits the

fluorescent tube that you want to use. They can be sourced from

specialist solar, camping, off-road or similar suppliers dedicated to low

voltage equipment. The inverter used here is designed to operate

36W tubes.

Inverters must be wired strictly as per the manufacturers instructions.

The Inverter is connected to the battery via a socket and a power

switch which is suitable for the current load. It's also a good idea to

install a fuse to protect against electronic faults or short circuits

(refer to the Inverter manufacturers recommendations). The wiring used

must be suitable for the high voltages supplied by the inverter,

again refer to the inverter manufacturers recommendations.

|

|

|

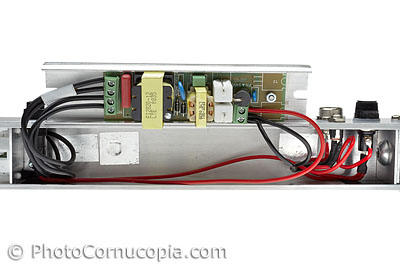

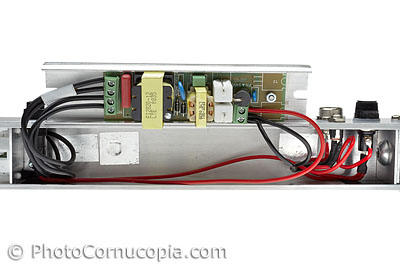

| The

12 volt inverter fits neatly into the housing. The inverter produces

high voltages to drive the fluorescent tube so safety precautions must

be taken to ensure that these high voltages can never be contacted

accidentally. |

|

The fluorescent

lamp holders are often called tombstones and are available in many

shapes and sizes depending on their intended application and how they

will be attached. These are for T8 tubes.

|

|

|

|

| The

tombstone lamp holders are fitted on a simple angle bracket and wired

from below. |

|

Identical

tombstones are used at both ends of the housing.

|

The housing is made from a

40mm aluminium extrusion because that particular extrusion allowed the

inverter and other components to fit neatly inside. You might have to

use a larger extrusion depending on the inverter used. Aluminium

extrusions are available in a bazillion sizes and you can even have them

moulded to your own dimensions if you really want to, but you'll

probably have to make a 250Kg batch of them! It's easier to just see

what you can get from importers or suppliers in your area and just make

it work for you.

Black non reflective tape was used on the external surfaces of the

housing so that it didn't reflect any ambient lights and therefore

appear in images.

|

|

|

| The aluminium housing has a socket for power. The battery

holder is attached to the housing using Velcro hook and loop strips and

can be positioned so that it doesn't interfere with holding the light. Any kind of 12

volt battery could be used. |

|

The base of the light

was also fitted with a Female 16mm or 5/8th inch adapter to allow

the light to be fitted to light stands for easy storage between

shots. This also allows the lamp to be held above the car with a

suitable extension or 5/8th inch rod.

|

The 12 volt power

source is a group of 10 AA NiMH 2000mHh batteries which are wired in

series. I used NiMH batteries because I have lots of them, as do most

working photographers. This battery pack is capable of powering a 36W

tube for approx 1 hour but you could use higher capacity NiMH

batteries, or just bring a spare set. Any 12 volt battery could be used as long as it is

capable of supplying the moderately high continuous current of 1.5

Amps. NiMH batteries are quite good at supplying that kind of current

for extended periods and I found that the batteries where cooler after

1 hour of continuous operation than they are after heavy use in a Canon

580EXII flash!

Does it work?

Yes, and quite well too. It's not too heavy, cumbersome, dim or

anything else. It provides an evenly distributed light at about the the

right intensity however this will always depend on which aperture and

ISO you want to use.

For those unfamiliar with automotive light painting a full description

of the technique can be found in the article Automotive Lighting 8:

Painting with Light.

The test images

above where shot with a 6500K light source to cause the background colour to

contrast dramatically with the light painted image

however a different colour tube could have been used for a different effect. If a

30000K

tube had been used, which is a similar colour to the ambient Sodium lamps, then the background would

look more natural and less amber. 5000K tubes are also quite common and balance fairly

well with flash and Metal Halide street lights (the white ones). In this

case however the background lighting was from a mix of Sodium and Metal

Halide lamps so it would be impossible to balance both simply by using a

specific colour temperature tube.

Fluorescent tubes

have a minor inherent disadvantage in that they take a little while to

warm up before they reach maximum light output. When the tube is first

switched on it is cold and may produce a full stop less light then when

it is warm. Once warm it will produce a relatively consistent light

even if switched off for short periods so in practice the difference in

light output is generally insignificant.

Why?

Why didn't I just use an LED strip? The LED's in LED strips are usually

spaced apart so their reflection in a car panel can potentially appear

as multiple lines instead of a continuous strip. Although steps can be

taken to diffuse these spots of light into a long continuous strip,

such as simply placing a diffusing material in front of them, a

fluorescent tube is inherently a much more evenly illuminated source so

is a better choice in this respect.

If you are looking for the cheapest option then just wander off to your

nearest hardware or aftermarket auto store where you can buy a very similar

fluorescent or LED 'work light' for relatively little cost. Such a light would need a few minor

modifications, maybe just a carefully placed reflector or cutter

(shield). However I wanted something that was potentially more sturdy, effective

and just bigger, so I

decided to make my own. But I'm an electronics geek and I like doing

that kind of thing anyway.